As synthetic intelligence (AI) expertise advances, the demand for higher-performing semiconductors is quickly rising. The event of recent supplies and progressive constructions to realize high-performance semiconductors has grow to be essential.

For the primary time globally, a 4-inch heterostructure fabrication expertise utilizing plasma-enhanced chemical vapor deposition (PECVD) has been developed. This breakthrough allows the manufacturing of low-power, high-performance semiconductors, surpassing the capabilities of conventional silicon-based expertise.

A analysis crew led by Senior Researcher Hyeong-U Kim of the Semiconductor Manufacturing Analysis Middle of the Korea Institute of Equipment and Supplies (KIMM), in collaboration with Professor Taesung Kim’s crew from the Division of Mechanical Engineering at Sungkyunkwan College, has achieved the world’s first profitable fabrication of a 4-inch heterostructures semiconductor with utilizing plasma expertise.

The analysis is featured in Advanced Materials and Energy & Environmental Materials.

This expertise is predicted to be relevant to AI semiconductors by using next-generation semiconductor supplies like TMDc.

TMDc (transition metal dichalcogenides) is a fabric candidate for next-generation semiconductors with atomic-level, 2D constructions providing silicon-like efficiency, low energy operation, and quick switching speeds. It’s significantly appropriate for neuromorphic methods and utilized in machine studying, deep studying, and cognitive computing. (e.g., molybdenum disulfide, MoS2), tungsten disulfide, WS2), and molybdenum selenide, MoSe2).

Utilizing PECVD tools, the analysis crew succeeded in producing two forms of 4-inch wafer-scale heterostructures. The primary kind, a heterostructure of WS2) and graphene, was fabricated by depositing a 1-nanometer (nm) tungsten (W) steel layer onto a graphene-transferred wafer, adopted by H2)S plasma sulfurization.

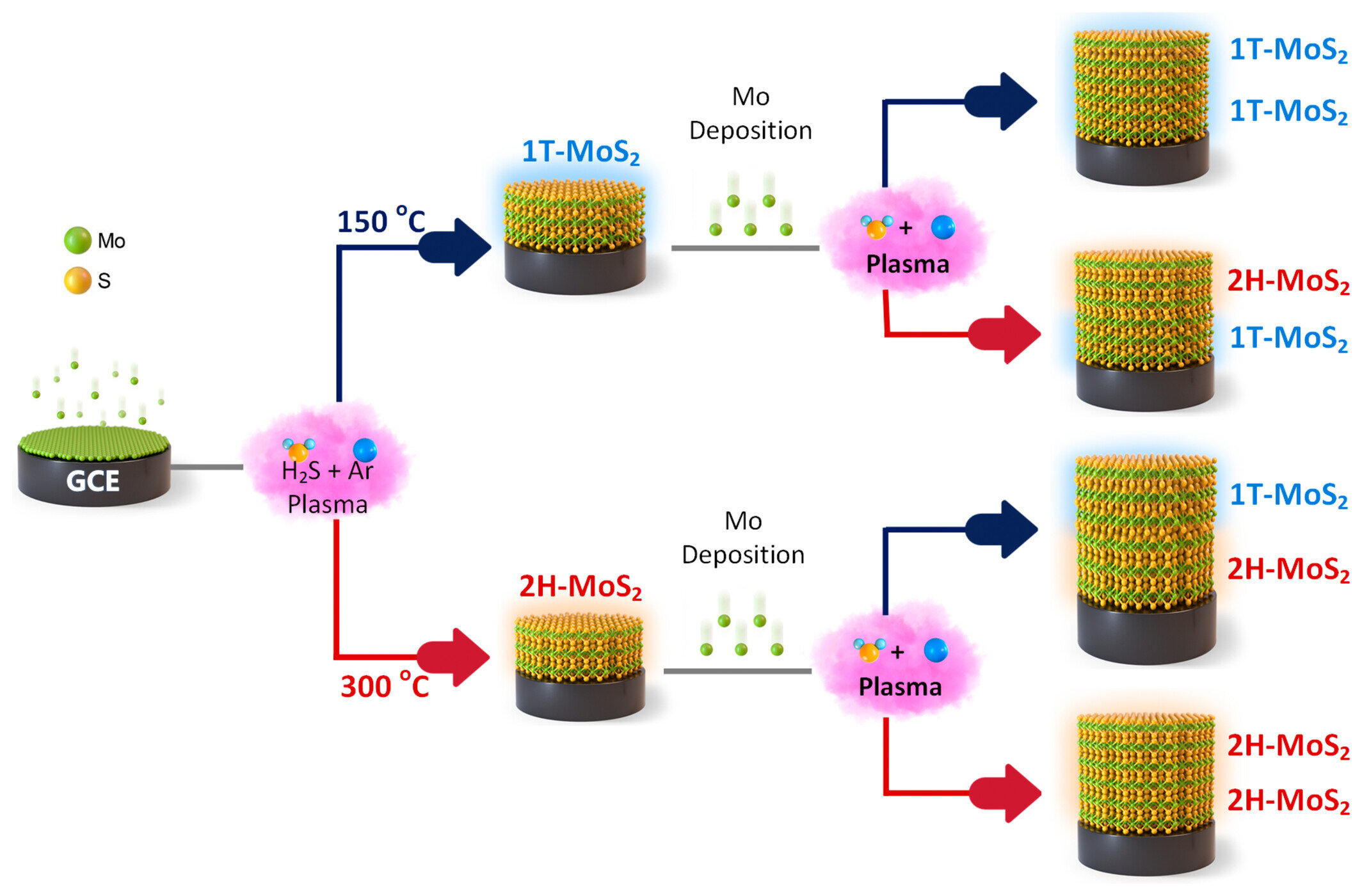

Moreover, the crew achieved a breakthrough with a metal-semiconductor heterostructure by combining two distinct types of molybdenum disulfide (MoS2)) as a skinny movie.

The metallic 1T section, with an orthorhombic construction, is metastable in comparison with the extra secure hexagonal 2H section, making large-area wafer manufacturing difficult. This new expertise allowed the crew to supply a 4-inch wafer within the 1T section and efficiently implement the 1T-2H heterostructure.

Conventional strategies for heterostructure, akin to stacking, had been solely allowed to small sizes of some μm and had reproducibility points. The crew overcame these limitations through the use of PECVD to manufacture a 4-inch wafer-scale heterostructure.

This breakthrough permits for the event of a 3D built-in construction, which considerably reduces power loss and heat dissipation, resulting in enhanced efficiency and energy efficiency—key elements for low-power, high-performance AI semiconductors.

KIMM’s Senior Researcher Hyeong-U Kim acknowledged, “This newly developed expertise not solely fulfills wafer-size and reproducibility necessities but additionally permits experimental validation beforehand restricted to tutorial analysis.

“Utilizing PECVD, a extensively employed software within the semiconductor business, this expertise affords excessive potential for mass manufacturing, probably contributing to developments in AI semiconductor efficiency and commercialization.”

KIMM has secured authentic expertise for the 2 types of 4-inch heterostructure wafer fabrication by means of patent registrations in each the US and South Korea.

Extra info:

Hyunho Seok et al, Electron Launch by way of Inner Polarization Fields for Optimum S‐H Bonding States, Superior Supplies (2024). DOI: 10.1002/adma.202411211

Kubra Aydin et al, Unlocking of Schottky Barrier Close to the Junction of MoS2 Heterostructure Below Electrochemical Potential, Vitality & Environmental Supplies (2024). DOI: 10.1002/eem2.12800

Quotation:

Advance in 4-inch heterostructure fabrication enhances AI semiconductors (2024, November 7)

retrieved 7 November 2024

from https://techxplore.com/information/2024-11-advance-inch-heterostructure-fabrication-ai.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.