Mining should harness expertise to “advance productiveness, sustainability and security,” PwC states. One essential expertise on this equation is cell computing, Michael Trafton* writes.

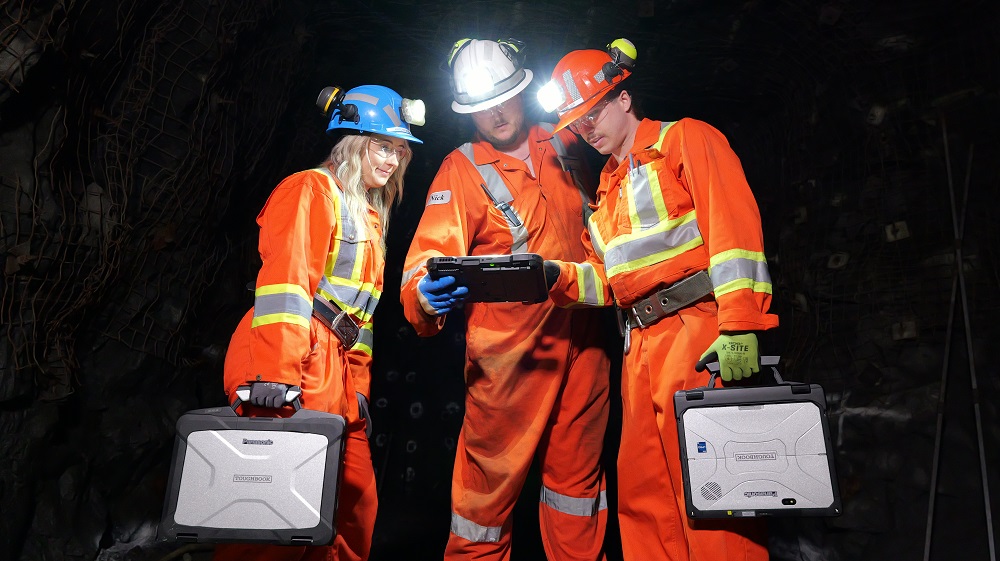

The mining expertise ecosystem consists of computing, equipment, instruments, wi-fi, IoT and extra. Rugged cell computing units – laptops, tablets, and 2-in-1s – are important to this combine. They join miners, groups and knowledge to central command facilities. They’re the lens with which miners can handle, management, replace and restore equipment. They’re instruments to function extra productively and securely. And, in contrast to consumer-grade units, they’re engineered “rugged” to ship optimum ranges of warmth, water, mud, grime and drop resistance.

Whether or not an operator, technician, shift supervisor or a security supervisor, mining professionals want a dependable computing companion to assist overcome trade challenges in 2025 – and carry out extra productively.

Digitise monitoring, reporting and communication

Over the previous few years, mining executives have pushed digital investments. These included connecting organisational capabilities, repositioning expertise for progress and empowering the workforce. Digital investments had been made to assemble extra info, make it simpler to report and share info and velocity up time to behave on knowledge. For instance, boosting productiveness and knowledge gathering by working resource-intensive, CAD-based survey software program functions. Engineers, geologists or planners are pushed info to offer a direct view of knowledge captured within the mine. That retains folks safter and permits mining operations to run smarter.

Core to this operate are rugged cell computing units. They permit digital reporting from any location. They permit staff to view plans, drawings, or orders from any setting. They even present a window for controlling and monitoring semi-autonomous or autonomous fleets, or drones, for instance. The problem is that computing calls for – pushed by the development of software program and proliferation of knowledge processing wants – are laborious to satisfy. Extra knowledge means extra energy necessities. To keep away from breaking digital chains within the area, computing options should steadiness processing capabilities with reliability and longevity.

Optimise deployment, upkeep, and restore of automobiles and gear

Automobiles are getting smarter. Machines are more and more pushed by chips. Diagnostic instruments are as a lot software program primarily based as they’re {hardware}. This makes the deployment, upkeep and restore of equipment within the area a tougher proposition. It isn’t only a matter of reskilling or hiring new engineering expertise. It’s ensuring these people have the means to run diagnostics on web site, view intricate blueprints and different software program applications mid-repair, and, in some cases, run updates in actual time. Not like in an workplace or enclosed setting, mining websites aren’t conducive to working energy shops and cables and wires on the level of service. And it will be extraordinarily pricey and time-consuming to ship each restore off-site or to a central seller location.

The money and time financial savings of developments to restore are unquestionable. Developments in edge computing are serving to distant staff and area service groups optimise deployment, upkeep and restore of automobiles. And, by conserving staff related, managers have a holistic view into scheduling and resourcing in close to actual time. Time and productiveness financial savings by optimising useful resource allocation and conserving machines and automobiles as near mining websites as they are often, will show an asset amid making an attempt occasions.

Realise the worth of AI and automation

It’s laborious to depend the variety of occasions a buyer or prospect has requested concerning the worth of AI and automation – and, in the end, the way it may assist their mining operation. AI and automation are evolving, however making that promise a actuality on the tough, distant frontlines of mining isn’t simple.

Mining leaders are in search of AI to assist velocity up and increase data-intensive duties and ship faster time to worth on essential info. Packages working on rugged cell computer systems monitor heavy equipment efficiency, measure yield and allow GPS-based mapping and surveying. Having the ability to course of info on web site and routinely flag or alert abnormalities in knowledge will change the sport for miners because the trade transforms.

For instance, when machine efficiency, yield weight, or scheduled workflow falls outdoors a sure threshold, applications can routinely alert a supervisor or sound an alarm so folks know the place to direct consideration. The identical goes for measuring manufacturing cycle knowledge towards goal plans, utilizing predictive analytics to grasp the chance of attaining objectives and what property have to be reallocated to make that work. Mining operations need to do extra with knowledge. Having the computing instruments within the area could make that occur – saving time, cash and defending towards pricey downtime.

What you want from a companion

For companies within the mining trade trying to digitise, the journey could be a difficult one. Balancing transformation whereas working across the clock to satisfy present calls for is hard.

Mining leaders are asking: are our computing instruments engineered to deal with the rigor of frontline mining? What does service and assist appear to be of those instruments, from day one to years down the road? Are we positioning people and groups to take advantage of knowledge, each under and above floor?

In 2025, I count on to see organisations re-evaluate their computing fleet to maximise the impression of knowledge to enhance operations.

*Michael Trafton is Enterprise Improvement Supervisor of Panasonic Join North America